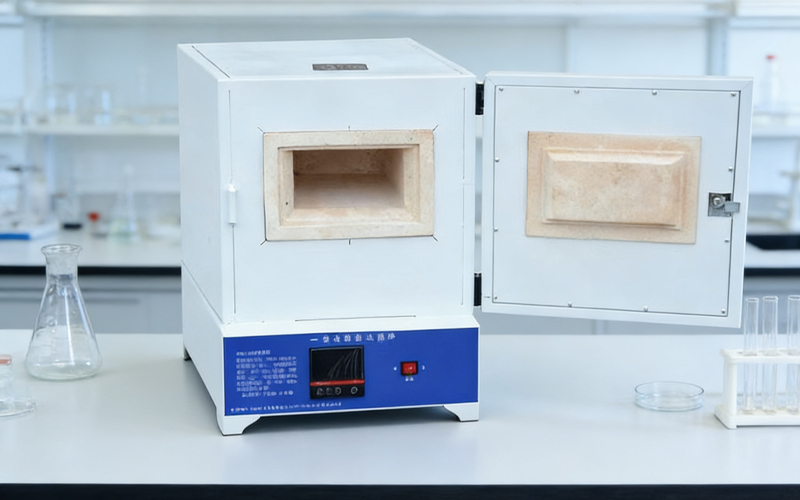

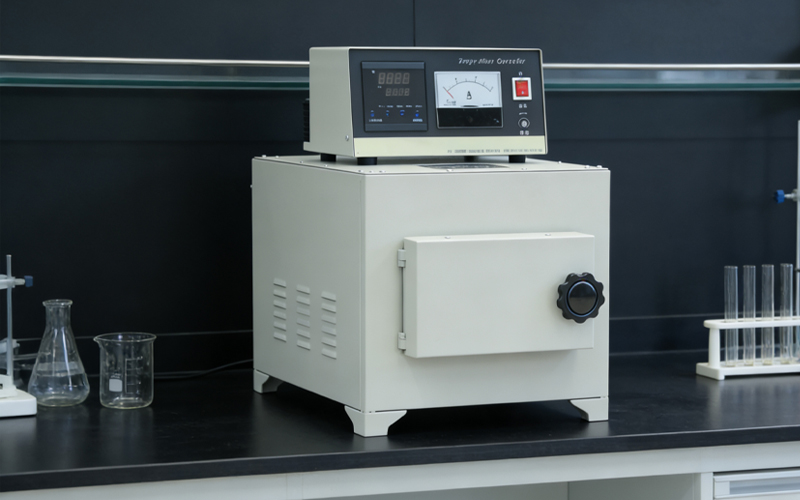

A muffle furnace, also known as a box-type resistance furnace, is one of the most commonly used high-temperature processing instruments in laboratories. Its working principle is to convert electrical energy into heat through heating elements and achieve a stable, controllable high-temperature environment inside a sealed chamber. The term “Muffel” comes from German, meaning “insulated chamber,” referring to the high-temperature working zone inside the furnace chamber.

Modern muffle furnaces typically use lightweight refractory ceramic fiber as the inner lining, while heating components are often made of silicon carbide rods or molybdenum disilicide rods. These designs allow the furnace to easily reach temperatures ranging from 1200°C to 1600°C, meeting the demands of materials science, chemical analysis, and high-temperature process research.

In scientific experiments, muffle furnaces handle tasks such as ashing, incineration, melting, calcination, and sintering—making them essential tools for ensuring repeatable and controlled high-temperature procedures. With the application of intelligent temperature-control technologies, Labant muffle furnaces perform exceptionally well in heating rate, temperature stability, and operational safety, providing precise thermal environments for various sample types.

I. How to Choose Different Structural Types of Muffle Furnaces?

To meet the needs of different sample forms and processes, muffle furnaces come in several common structures:

1. Box Furnace (General Purpose)

Square structure with a front-opening door

Large chamber volume with uniform temperature distribution

Commonly used for ashing, sintering, and general sample incineration

The most widely applicable option and a standard model for most laboratories

2. Tube Furnace (For Small Samples & Atmosphere Control)

Equipped with a quartz or alumina tube inside the chamber

Can be connected to vacuum systems or protective gases

Suitable for small-batch samples, directional heating, or experiments requiring special atmospheres

Widely used in universities and research institutions

3. Atmosphere Furnace (Controlled Reaction Environment)

Fully sealed structure with independent gas inlet and outlet

Door frame equipped with high-temperature sealing rings

Ideal for oxidation, reduction, nitridation, and other atmosphere-sensitive reactions

4. Pit Furnace (Vertical Loading)

Furnace chamber arranged vertically with a top-opening lid

Supports mechanical arms, lifting hooks, or large crucibles

Suitable for vertically loaded samples or large containers

II. Scientific Sample Handling: Key Factors That Influence Results

To obtain stable and reliable experimental data, samples must undergo proper preparation before entering the muffle furnace.

① Sample Pre-Treatment

Solid samples: grind and sieve to ensure uniform particle size, typically below 1 mm

Liquids/pastes: use quartz crucibles or other non-reactive containers

Solvent-containing or organic samples: pre-dry in a fume hood at low temperature to remove volatiles

High-moisture samples: dry to constant weight to prevent splattering or bursting during heating

② Crucible Selection Principles

Different crucible materials vary significantly in temperature resistance and chemical stability:

Porcelain crucible (≤1000°C): suitable for routine ashing and incineration

Alumina crucible (1000–1600°C): excellent high-temperature resistance

Quartz crucible: good acid resistance but poor alkali resistance

Platinum crucible: highly inert and ideal for high-precision analysis, but expensive

Choosing the correct crucible is essential for preventing contamination and improving experimental accuracy.

III. Typical Experimental Applications

1. Ash Content Determination

Common in food, coal, and environmental fields.

Process: pre-carbonization → high-temperature incineration → cooling and weighing → calculating ash content.

2. Ceramic Sintering

Sintering densifies ceramic powders by controlling heating rate, holding time, and cooling curve.

Labant furnaces offer excellent temperature uniformity, enhancing sintering consistency.

3. Pyrolysis or Thermal Decomposition Studies

Often performed using stepwise heating to study decomposition behavior and thermal stability.

Quartz boats can be used to collect gaseous products or monitor mass changes.

IV. Maintenance and Safety Guidelines for Muffle Furnaces

To ensure stable performance and prolong service life, follow the recommendations below:

1. “Baking” Before First Use

Also necessary after long periods of inactivity:

Heat to 200–600°C and hold for several hours to remove moisture absorbed by the chamber.

2. Avoid Continuous Operation at Maximum Temperature

Operating at the upper limit significantly shortens heating element lifespan.

Recommended: operate 50°C below maximum for longer stable cycles.

3. Environmental Requirements

No conductive dust or corrosive gases

Humidity below 85%

Temperature controller should operate between 0–40°C

4. Watch for Vapors When Heating Oily Samples

High-temperature vapors may corrode heating elements.

Use sealed containers or increase exhaust ventilation.

5. Regular Inspection & Calibration

Check:

Electrical circuits

Thermocouples

Temperature control system

Indicators

For precise experiments, calibrate instruments using a potentiometer.

6. Do Not Overlook Chamber Cleaning

Keeping the inner chamber free from oxides helps maintain temperature uniformity and extend lifespan.

V. The Value of Muffle Furnaces in Research and Testing

A muffle furnace acts as a high-temperature platform in laboratory systems. It not only provides a controllable thermal environment but also supports essential processes in material science, chemical analysis, and environmental testing.

With Labant’s high-precision temperature-control technology and robust structural design, users can achieve stable, repeatable, and verifiable experimental results more efficiently.

From ashing to sintering, from thermal decomposition to ceramic firing, Labant muffle furnaces serve as reliable partners in any laboratory, safeguarding research efficiency and data quality.

Follow on WeChat

Copyright @ 2024 Shanghai Welso Technology Co.,Ltd.